- Key Market Insights

- It reveals that the Saudi valve maintenance market is experiencing significant growth, with the oil and gas sector commanding 35% of the market share. The distribution of industrial valves shows diverse applications across various sectors, reflecting the increasing demand for reliable maintenance services in industries such as petrochemicals, refining, and manufacturing.

ALFA CORE Saudi Arabia, the parent company of RASIS Egypt,provides a comprehensive overview of on-site valve maintenance services, highlighting its expertise in this critical sector. The content includes detailed information on various valve types, advanced maintenance technologies, industry standards, and market analysis specific to the Saudi industrial landscape.

Why Pipeline Valves Maintenance in the Oil and Gas Industry?

- Pipeline valves are essential components in the oil and gas industry, playing a crucial role in ensuring the efficient, safe, and reliable operation of pipelines. Below are the key reasons that highlight the importance of pipeline valve maintenance in the oil and gas fields:

- Flow Control

- Valves regulate the flow of oil, gas, or other fluids through pipelines. By controlling the valve's opening and closing, operators can adjust the flow rate, ensuring the system operates efficiently.

- Pipeline Isolation

- Valves are vital for isolating sections of the pipeline for maintenance, inspection, or emergency situations. This minimizes disruptions to operations and enhances safety.

- Pressure Management

- In oil and gas pipelines, pressure fluctuations can lead to equipment damage or pipeline failures. Valves help to maintain and manage optimal pressure levels, reducing the risk of accidents and improving system stability.

- Emergency Shutdowns

- In the event of leaks, ruptures, or other emergencies, valves can be quickly closed to stop the flow, contain the issue, and protect personnel, the environment, and infrastructure.

- Safety Assurance

- Valves play a critical role in ensuring safety by preventing overflows, backflows, or cross-contamination between different fluids. For example, check valves prevent reverse flow, which could damage pumps or compromise pipeline integrity.

- Maintenance and Repairs

- Valves allow for routine maintenance by isolating sections of the pipeline without the need to shut down the entire system. This ensures continuous operation and extends the lifespan of the infrastructure.

-

Environmental Protection

- By controlling leaks and spills through timely isolation or shutdown, valves help minimize the environmental impact of oil and gas operations.

- Pressure Relief and Blowdown

- Relief valves are essential in releasing excess pressure to prevent catastrophic failures, while blowdown valves remove unwanted gas or liquid from the pipeline, improving system efficiency and performance.

- Adaptability to Operating Conditions

- Valves can be automated and integrated into advanced control systems, enabling real-time monitoring and management of pipeline operations, even under extreme conditions.

Onsite Pipeline Valves Integrity Team Activities

-

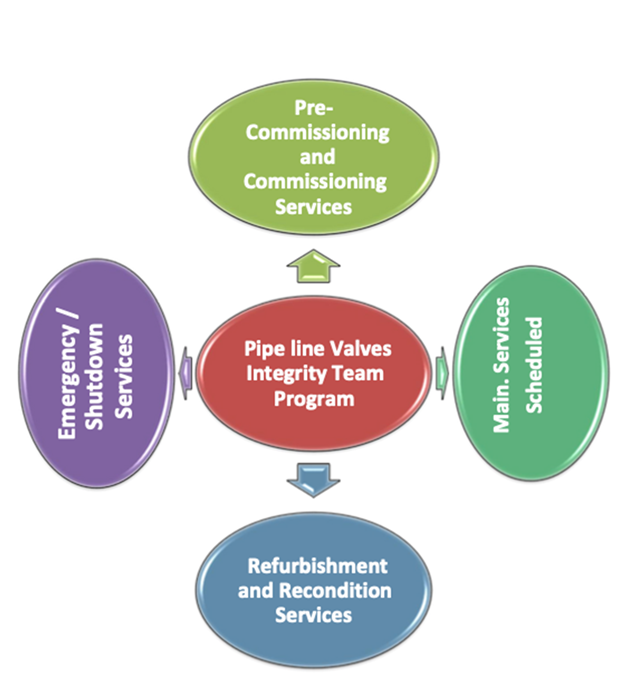

ALFA Valve Integrity Management System refer to the integrity of Valve system elements, these

elements consist of careful handling and storing of valves prior to installation, as well as following correct

procedure during pre-commissioning, commissioning, operating and maintaining the valve.

The integrity of all these elements ensures more efficient and safe operation with reduced chance of production

loss and/or isolation failure.

All the above elements are recorded, reported and analyzed through a computerized Database system.

Valve Integrity Management System (VIMS) Services are:

❑ Pre-Commissioning/Commissioning Services.

❑ Scheduled Maintenance Service.

❑ Emergency, Shutdown Services

❑ Machining / Refurbishment Services.

Pre-Commissioning and Commissioning Activities

-

Pre-Commissioning Services:

-

Create proper procedures for valve handling, transportation, and storage to prevent contamination and damage of the valve assembly.

-

Review/Correct the valve selection parameters based on the application required.

-

Visual Inspection to ensure that all valve components are as per the design drawing (injection fitting, body vent/drain, gearbox, etc.).

-

Replace the factory grease with high-quality synthetic lubricant, unless it was initially ordered filled with synthetic grease.

-

Function and hydrostatic test the installed valves.

-

Commissioning Activities:

-

Identify and determine the valve location and specification according to the PFD (Process Flow Diagram).

-

Inspect the valves after installation to ensure proper installation and detect any missing parts.

-

Top up the valve cavity with synthetic grease.

-

Function and pressure test the installed valves.

- Tag each valve with the ALFA or RASIS tag number, which will be used for tracking the valve and creating history records for pipeline valve systems.

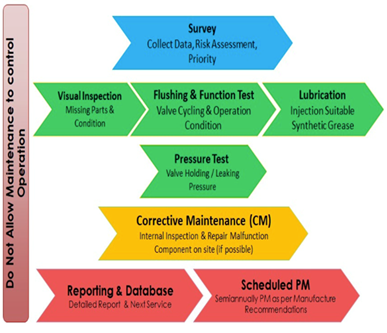

- Scheduled Maintenance Activities:

- Thousands of valves in every sector of the oil and gas industry are scheduled for replacement every year, causing loss of production due to the lack of maintenance. By applying ALFA or RASIS scheduled maintenance services, the valve reliability and integrity will be improved, reducing operational risk and downtime. Scheduled maintenance is divided into two categories:

- ▪ Preventive Maintenance (PM):

-

Visual Inspection

-

Cavity flushing

-

Function test

-

Lubrication

-

Valve Packing Replacement (If Required)

-

Pressure test

- ▪ Corrective Maintenance (CM):

-

Repair malfunctioning valves on-site, as possible.

-

The un-repairable valves are repaired off-site, which can be performed in the ALFA or RASIS Client workshop.

-

As per the valve manufacturer’s recommendations, the valve PM schedule should be semi-annual. It may seem excessive, but a small investment in time and PM could potentially protect your investment.

Emergency and Shutdown Activities

-

This service is subjected to solve the unexpected/ suddenly valves problems, likewise it can

solve operation problems, decrease the loss time and reduce/eliminate unplanned

shutdown. This service covers the following:

▪ Preparing the bolts for fast and easy removal.

▪ Prepare the spare parts and valves which will

be used in shutdown.

▪ Evaluate and control Emission / leakage.

▪ Valve sealant (amount and type of sealant depend

on leakage rate, application and valve size).

▪ Repair the reported malfunction valve.

▪ Replace the damaged parts/ valves on line.

▪ Provide recommendations that reduce/prevent the occurrence of problems.

▪ In case of temporally solutions, we will submit full procedures to solve the

problems permanently.

In emergency cases, our services will void most of forced shutdowns. Well Organized

management of planned shutdown, will lead to reduction of shutdown time and production

loss.

Contacts

Address:

Riyadh, Saudi Arabia

Phone:

+966546451947

+966564337314

Address:

Monufia, Egypt

Phone:

+201000969853

+201022223990

Email:

info@alfa-sa.net