FLANGE MANAGEMENT INTEGRITY

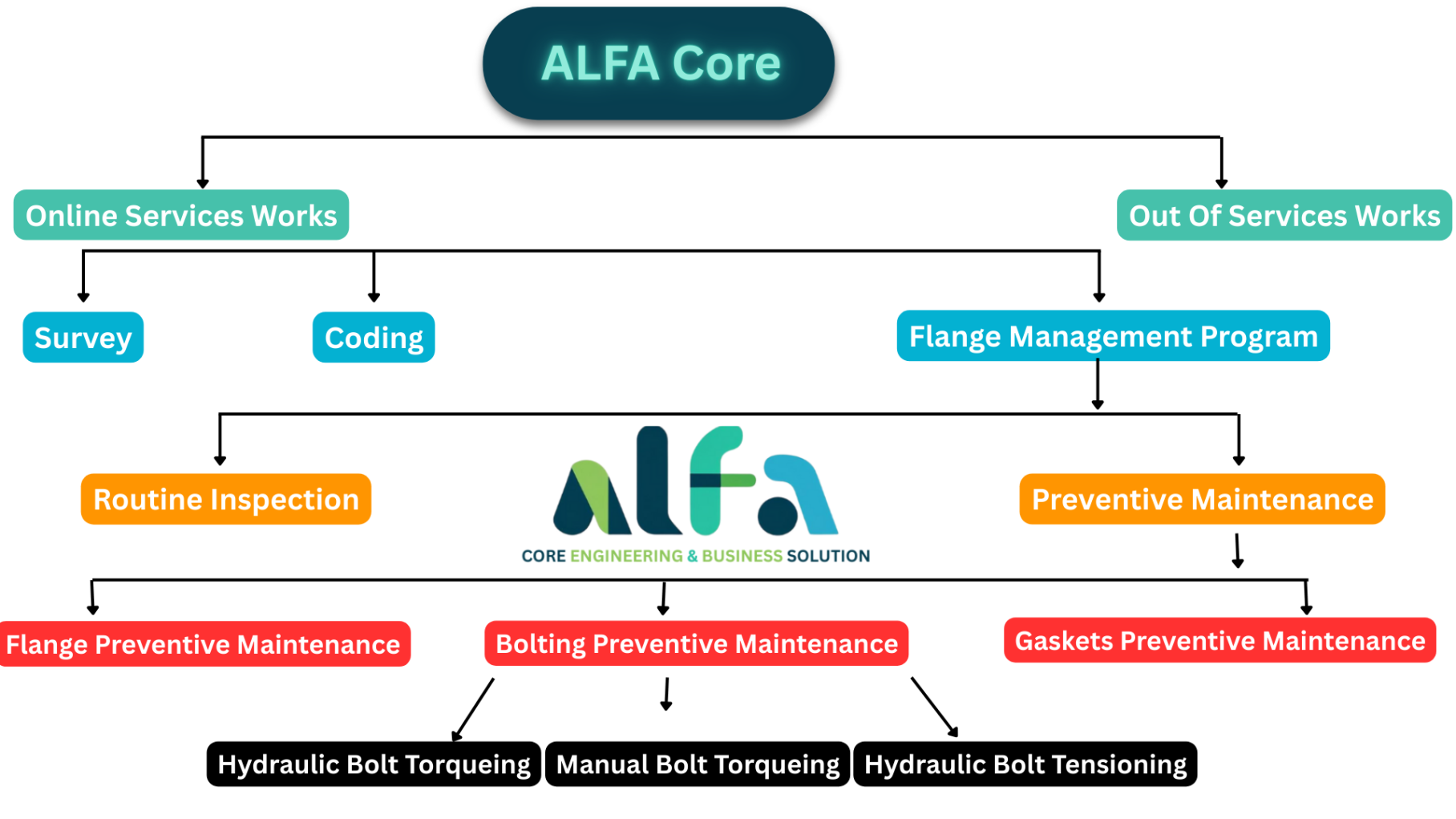

- ALFA CORE Saudi Arabia, the parent company of RASIS Egypt, provides delivers a fully managed Flange Management Integrity program services across the oil & gas, petrochemical, and refining industries in Egypt and the MENA region.

What is Flange Management Integrity and Why is it important?

- Flange Management Integrity is a systematic and engineered approach to ensure all bolted flange joints are installed, inspected, maintained, and documented properly.

- It plays a critical role in preventing leaks, ensuring safety, and maintaining plant reliability especially in high-pressure and high-temperature environments.

-

Historical data collection

-

Pressure / temperature media data

-

Flange, bolt and gasket details

-

Bolted joint evaluation

-

Analysis of design in accordance with International Standards (EN 1591-1)

-

Product combination and selection

-

Determination of optimal sealing parameters

-

Recommendations of any flange modifications required

-

Accurate establishment of required sealing loads

-

On-site inspection

-

Project management

-

Shutdown planning

-

Supervision

-

Inspection

-

Installation

-

Joint integrity monitoring

-

Improved safety

-

Reduced downtime

-

Assured reliability

-

Reduction of lost product

-

Leak and emission containment

-

Elimination of repetitive maintenance costs

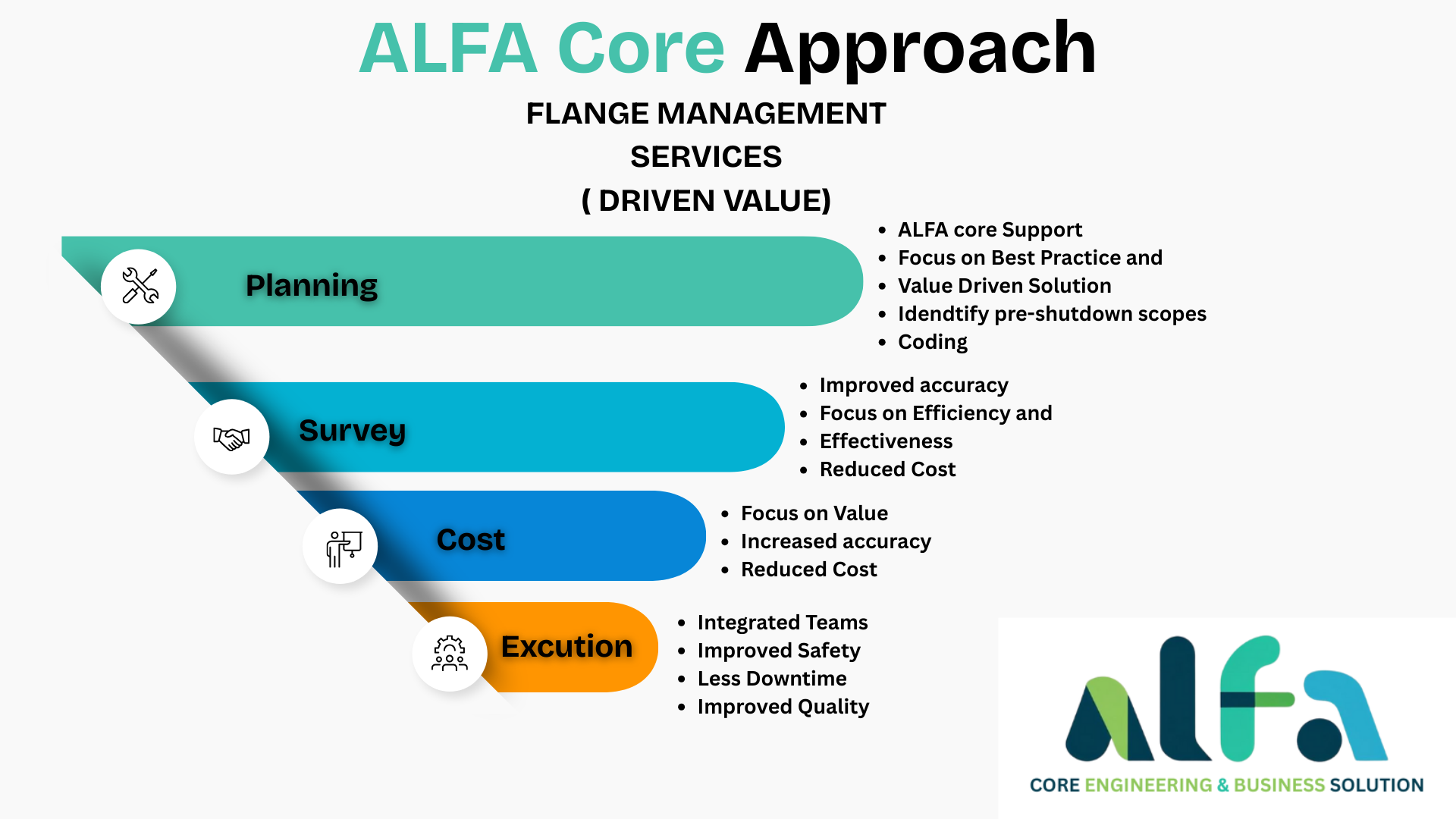

How does ALFA CORE Saudi Arabia implement Flange Management Integrity?

-

ALFA CORE Saudi Arabia, the parent company of RASIS Egypt, delivers a fully managed Flange Management Integrity program, including:

-

Evaluation of existing joints

-

Engineering design and product selection

-

On-site application and supervision

-

Documentation and reporting of each joint

-

Integration with a central database for full traceability

What is included in the Evaluation phase of Flange Management Integrity?

-

Historical data collection

-

Pressure and temperature media analysis

-

Flange, bolt, and gasket details

-

Bolted joint evaluation

-

Design analysis based on international standards (API 570, API 571, ASME PCC-1)

What services are offered during the Application phase?

-

On-site inspection of flanged joints

-

Full project management

-

Shutdown/turnaround planning

-

Supervision and certified installation

-

Joint integrity monitoring and control during and after operation

How does your reporting system work?

-

We provide a complete reporting system for every bolted joint under our Flange Management Integrity program. Each flange has a unique ID and a corresponding report that includes:

-

Inspection results

-

Assembly and torque values

-

Gasket and bolt data

-

Technician signature and timestamp

-

All reports are stored in a secure database, ensuring full traceability, compliance, and easy retrieval for

Contacts

Address:

Riyadh, Saudi Arabia

Phone:

+966546451947

+966564337314

Address:

Monufia, Egypt

Phone:

+201000969853

+201022223990

Email:

info@alfa-sa.net